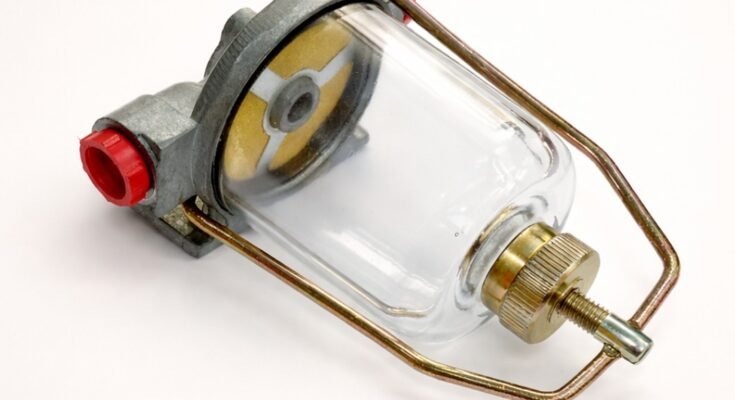

The object in the photo is a glass-bowl fuel filter / sediment bowl fuel strainer. It is designed to trap dirt, rust, and water from fuel before the fuel reaches an engine (often seen on tractors, small engines, generators, and older vehicles).

Why This Design Is Useful

A glass bowl fuel filter is popular because you can see contamination without taking anything apart. If you notice sediment at the bottom or water separating from fuel, you know it’s time to clean or service it.

Main Parts You Can Identify in the Photo

Clear glass bowl: lets you visually inspect fuel quality and collect debris/water.

Metal housing (top body): the main block that connects to the fuel line.

Inlet/outlet ports (covered with red caps in the image): where fuel enters and exits.

Bail wire / retaining frame: the metal strap that locks the bowl tightly to the housing.

Sealing gasket/O-ring area: prevents leaks between glass and housing.

Drain screw/valve assembly (knurled metal piece at the bottom): used to release trapped water/sediment or empty the bowl during service.

Internal screen/element (visible inside): catches fine particles before fuel flows onward.

How It Works (Simple Explanation)

Fuel flows into the housing through one port.

The fuel passes through a screen/filter element, which traps dirt and rust.

Heavier contamination (and often water) settles into the bottom of the glass bowl.

Cleaner fuel exits through the other port and continues to the carburetor or injection system.

Where You Might Find It

Tractors and farm equipment

Older diesel or gasoline engines

Marine engines (where water contamination is a common issue)

Generators and stationary engines

Common Signs It Needs Service

Engine hesitates, loses power, or stalls (restricted fuel flow)

Visible dirt or sludge collecting in the bowl

Water droplets/layer visible under the fuel

Fuel smell or dampness around the gasket (possible leak)

Basic Cleaning and Maintenance Steps

Turn off the fuel supply (or clamp the line if appropriate).

Place a container underneath to catch fuel.

Release the bail wire and carefully remove the glass bowl.

Empty and clean the bowl; wipe out sediment.

Clean or replace the screen/filter element if accessible.

Inspect the gasket/O-ring; replace it if flattened, cracked, or hard.

Reinstall the bowl and secure the bail wire evenly.

Open fuel supply and check for leaks before running the engine.

Practical Tips to Avoid Leaks and Problems

Do not overtighten the retaining mechanism—glass can crack.

Replace the gasket whenever you see seepage or after repeated services.

If you frequently find water, check fuel storage and consider a water-separating setup upstream.

Keep the ports and fittings clean to prevent new debris from entering during reassembly.

Why People Still Use It Today

Even with modern filter cartridges, this style remains valued for its easy inspection, simple servicing, and the ability to quickly confirm whether fuel contamination is the cause of an engine issue.